We are cultivating a new paradigm of responsible material sourcing which rooted in the fertile Terai region of Uttar Pradesh, where tradition and innovation grow side by side. Our ecosystem is built around organic cotton, banana fibre, hemp, flax, and botanical silk substitutes that are grown through intercropping systems that restore soil health, conserve water, and strengthen the nitrogen fixation of soil.

By cultivating food and fibre crops together, farmers strengthen both their food security and income stability, while turning seasonally waterlogged fields into productive, fertile land that enhances the quality and produce of every harvest. This model transforms conventional agriculture into a circular bio-economy, creating a steady supply of climate-resilient, traceable fibre cultivation with low-impact for conscious brands.

KOSH is turning the Terai into a living laboratory for sustainable fibre innovation offering brands a credible, scalable route to ethically sourced, high-performance natural textiles.

At KOSH, we believe colour should live and be cultivated but not to be manufactured. Our algae-based dye innovations harness one of the planet’s most ancient and regenerative organisms to create biological pigments that are non-toxic, biodegradable, and restorative to the environment and bring textiles to life without harming the earth.

Grown in controlled, circular systems, algae convert sunlight and carbon into natural colour through photosynthesis a process that purifies water and restores balance to the environment. From these living cells emerge hues of a palette that are biodegradable, skin-safe, and traceable, carrying the quiet intelligence of nature itself.

Through this fusion of living science with biotechnology and traditional craft, KOSH redefines colour as a renewable resource into art, transforming what once polluted into something that heals, connects, and endures.

At KOSH, we believe growth should follow nature’s logic of organic, balanced, and deeply rooted in community. We work through a “Tree Model” of the SPKOGSS system which is a structure that mirrors nature’s balance of roots, trunk, and canopy, ensuring strength, connection, and growth at every level.

The roots lie in artisan communities who have got this craft skill from generations transferred to them spread across villages who work from their homes and local clusters, supported by training, tools, and fair livelihoods. Branches and stems represent coordinators, supervisors that enable quality control, innovation, and knowledge sharing. KOSH management team acts as the trunk by linking these roots and branches to market collaborations. This structure transforms individual craftsmanship into a coordinated, large-scale ecosystem capable of meeting global standards without losing its human essence.

Together, these interconnected layers form a living, decentralized production system one that mirrors factory-level efficiency with community-centred flexibility. The model balances community empowerment with commercial viability, one that grows stronger through collaboration, creating textiles that are not only made by many hands but also allowing KOSH to stay true to its purpose: preserving heritage, enabling livelihoods, and creating measurable impact from the ground up.

At KOSH, the story of every textile begins with handspinning, a practice that transforms raw, natural fibres into living yarns. Using traditional charkhas, our artisans spin fibres such as organic cotton, banana, hemp, etc. applying centuries-old techniques refined by experience and care.

This manual process allows each strand to retain its natural irregularity and tensile strength, giving the yarn a distinctive texture and breathability that machine spinning cannot replicate. The rhythm of the spinner’s hand, the gentle twist of the fibre, and the slow pace of creation together produce yarns that are alive — tactile, imperfectly perfect, and deeply human.

Handspinning at KOSH is not just a production method , it is a philosophy of making that values patience, skill, and connection between the maker and the material.

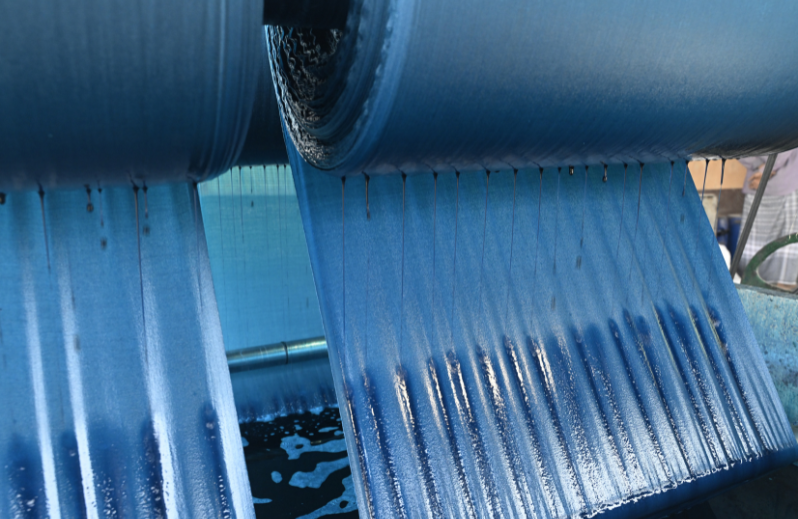

At KOSH, colour is not forced — it’s invited. Our cold dyeing process preserves the living essence of natural pigments by allowing colour to bond with fibre without the use of heat or harsh chemicals. This gentle method reflects our philosophy of working with nature, not against it.

In cold dyeing, pigments derived from algae, are prepared and allowed to infuse into the fabric at ambient temperatures. The absence of heat ensures that both the fibres’ natural strength and the pigments’ bio-intelligence remain intact, producing colours that are soft, nuanced, and enduring.

This process not only conserves energy but also reduces water use and chemical discharge. Each dye bath becomes a living medium ,one that leaves no toxic residue and can often be repurposed as organic compost or irrigation water.

The result is a palette born from patience and purity,colour tones that speak of earth, air, and time. Every cold-dyed textile from KOSH is a quiet proof that innovation and ecology can coexist beautifully, colouring the future of sustainable design.

At KOSH, weaving is a dialogue between innovation and heritage where contemporary patterns meet ancient rhythm. The process begins with the preparation of the warp (longitudinal threads) and the weft (horizontal threads), carefully aligned to create balanced tension and texture. Artisans work with natural-fibre yarns and bio-based dyes, translating design concepts into tangible forms through rhythmic, intentional movements. Each fabric is woven on traditional wooden looms, operated by artisans whose knowledge has been passed through generations.

Every metre of cloth carries the signature of the weaver, visible in the subtle irregularities and variations that give handwoven textiles their soul. This slow, human-centred process ensures minimal energy use, zero waste, and complete traceability, proving that craftsmanship can coexist with scalability. Our handweaving clusters are an example where the art of interlacing threads becomes a language of design and discipline

At KOSH, stone washing process is designed to bring this story to life, using natural stones and controlled washing techniques to soften the texture of handwoven textiles while preserving their integrity and environmental purity.

In this process, fabrics are gently tumbled with pumice and river stones, allowing natural abrasion to open the fibre surface and create a beautifully lived-in feel. Unlike chemical softening, stone washing relies on physical interaction rather than synthetic additives, achieving natural softness, breathability, and a subtle vintage character that enhances the fabric’s authenticity.

Each piece is then rinsed and sun-dried, allowing the textile to settle into its final form of supple yet strong, refined yet organic. The process uses minimal water and no harmful chemicals, aligning with our commitment to low-impact production and circular design.

For us stone washing is more than a finishing technique , it’s an act of refinement that honours both craftsmanship and nature’s patience, revealing the quiet beauty within every fibre.